Subscribe to the latest news

Sign up to receive updates on sustainable solutions and low-carbon materials from Betolar.

View a video

Press releases, company releases and management transactions

Articles

Success cases from our customers

Upcoming and past events

Learn more about our story and Betolarians

Interested in working at Betolar?

Become one of our trusted partners

Fill a form to contact us and we'll get back to you

Betolar careers

Reckon you are just the forward thinking professional we are looking for? Let us know about you!

Check available job positions

Check available job positions

Interim report

Check the webcast recording of our Q3 Business Review

View webcast

View webcast

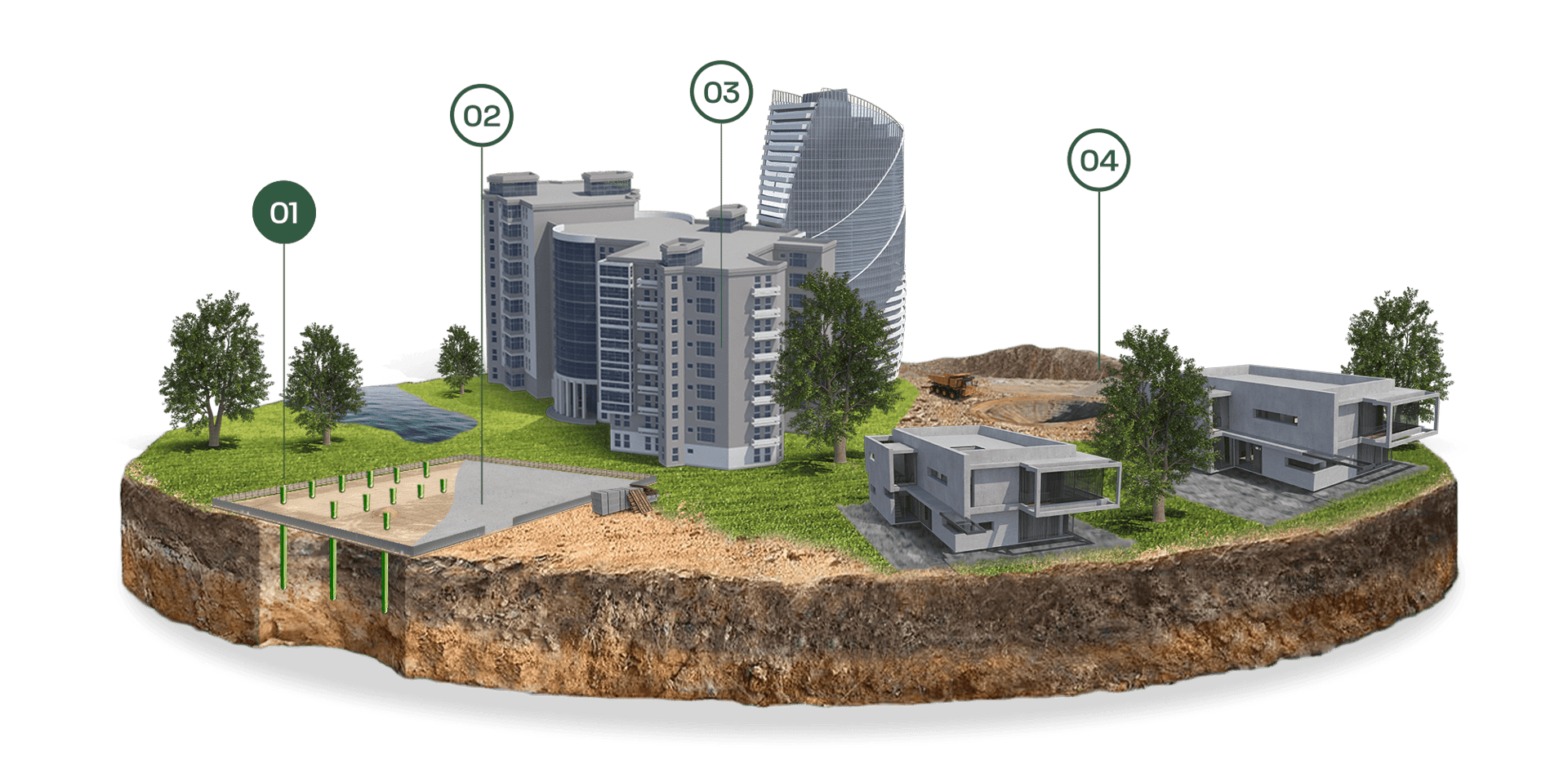

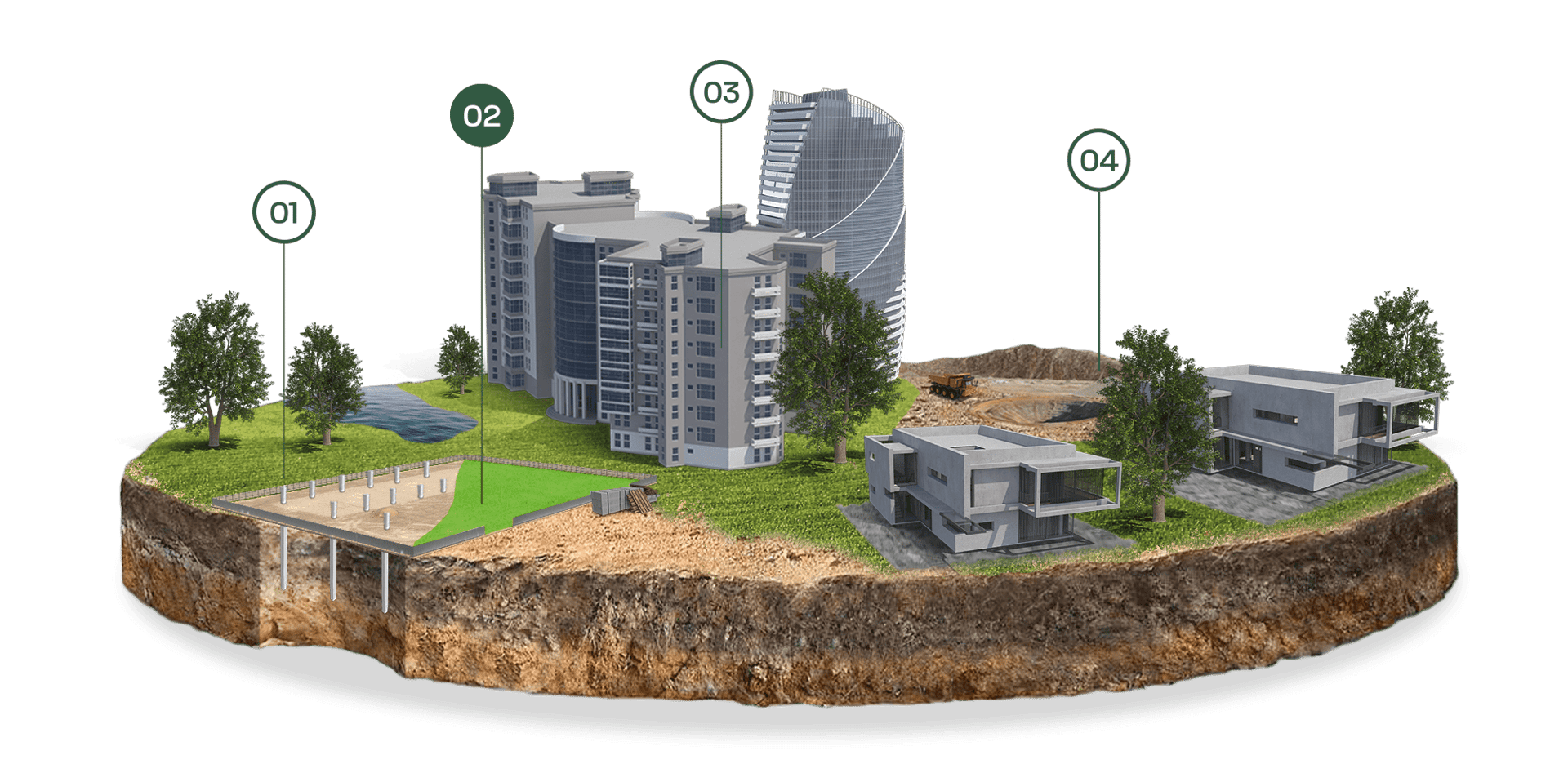

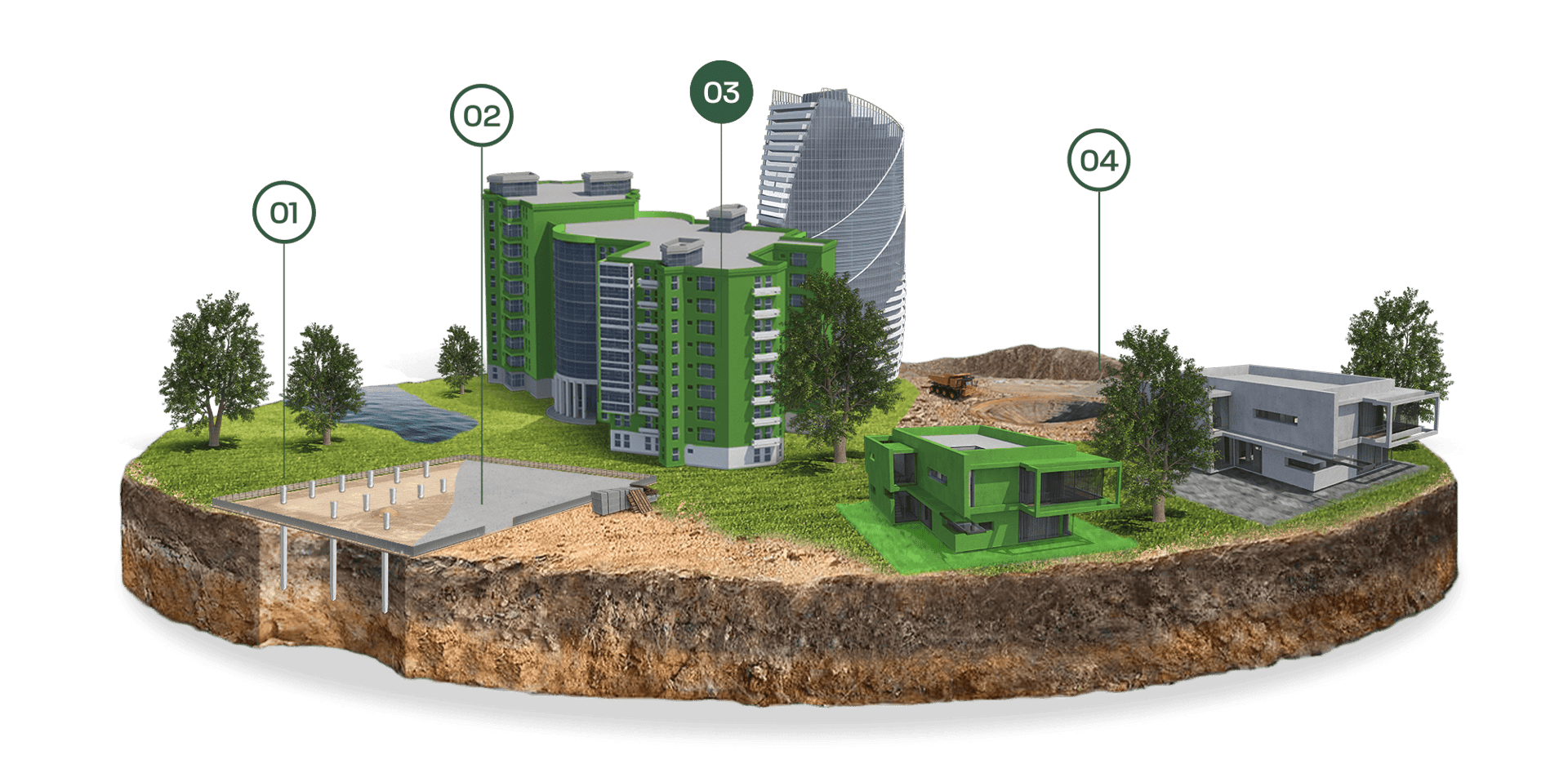

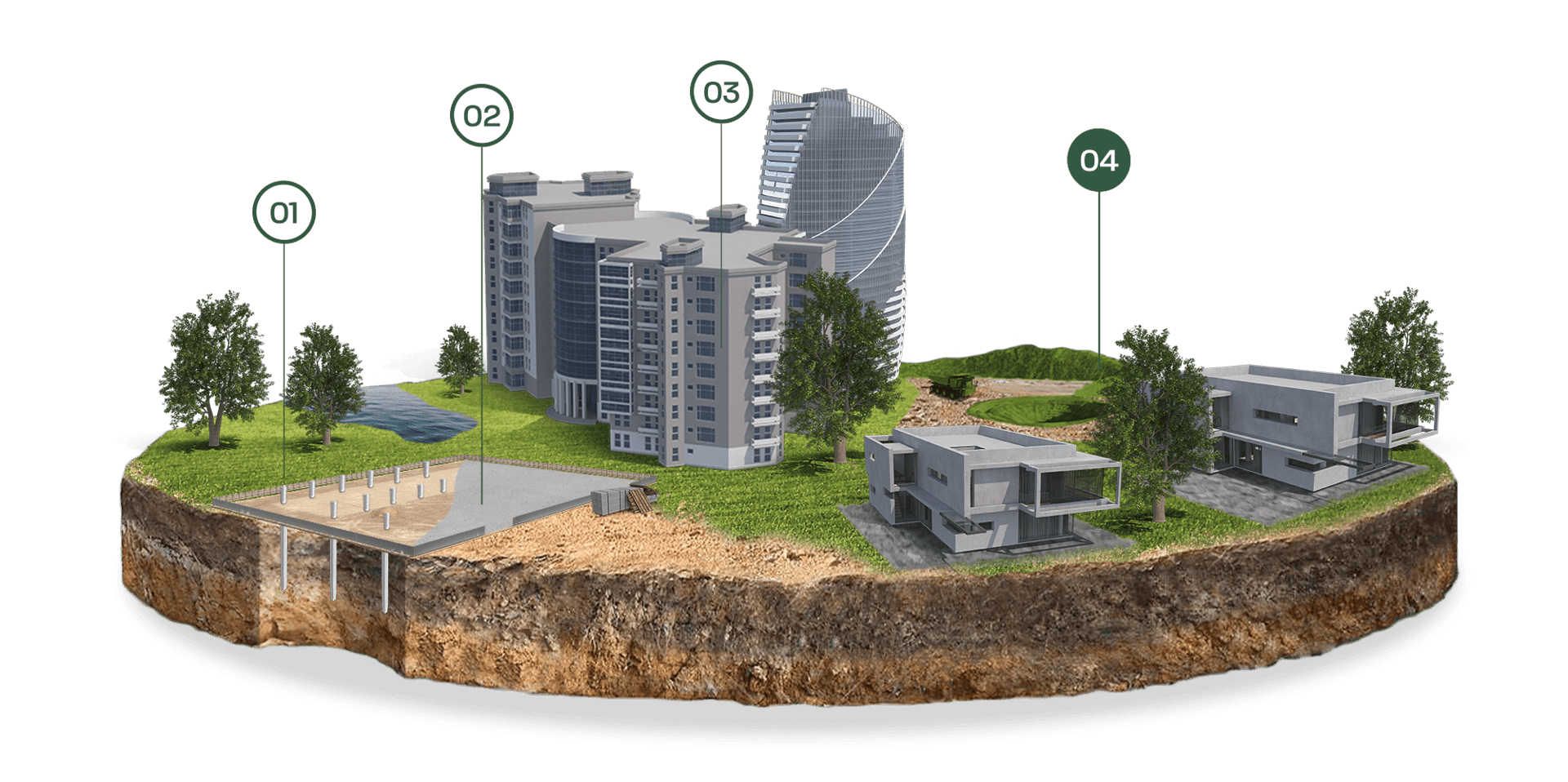

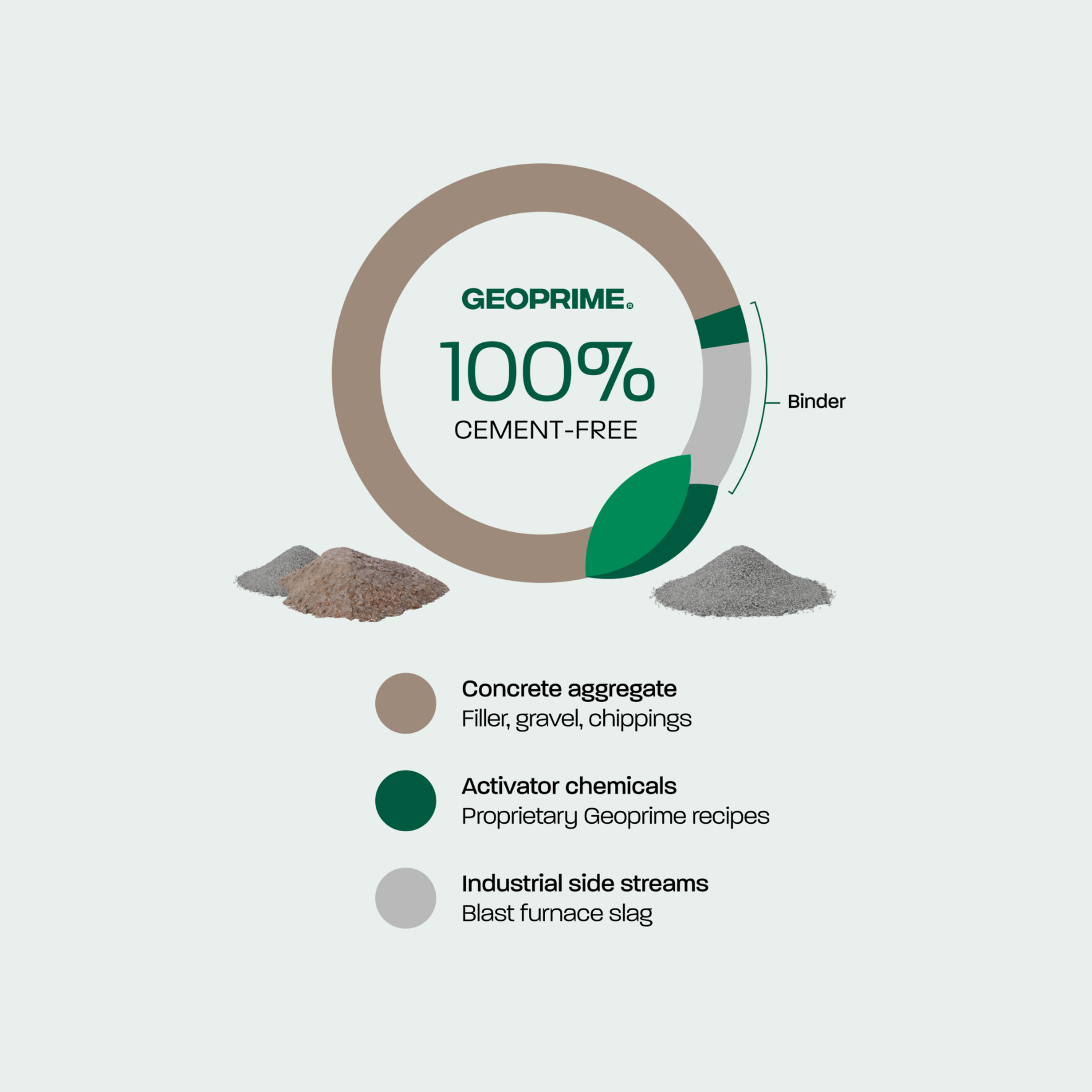

What is Geoprime®?

Geoprime is a sidestream-based low-carbon construction material innovation and a sustainable alternative to cement.

Completely equivalent to traditional cement-based concrete it is a reliable and safe solution for a range of applications.

Enables up to 80% lower

CO2 emissions

Enables up to 100% cement-free solution

Same strength as concrete

environmental challenge

The construction industry is one of the most polluting industries in the world. The culprit is cement, the main raw material of traditional concrete.

The extraction of limestone required for the production of cement consumes an enormous amount of virgin resources. In addition, the lime is heated at a high temperature, which releases a large amount of carbon dioxide into the air.

At the same time, industrial production generates billions of tonnes of waste and sidestreams every year which could be utilized as raw materials.

Geoprime is the solution.

Discover more about the Technology and its advantages.

TECHNOLOGY

The Geoprime products are based on a geopolymer solution. A geopolymer is an inorganic polymer that can be used for creating new materials, for example, to replace cement in concrete.

Geoprime concrete consists of components from industrial sidestreams and Betolar’s proprietary Geoprime activator.

COMPONENTS and characteristics

The continuously developing, optimised recipe is based on Betolar's proprietary research and development.

Advantages of Geoprime compared to traditional concrete made with Portland cement.

QUALITY

Geopolymers have been studied for decades in various research institutes globally. Our research team has extensively explored the properties and behaviour of the Geoprime material and products in different applications and conditions.

Geoprime has been tested according to concrete standards and meets all essential criteria of concrete. This makes Geoprime a safe and durable solution for diverse applications and varying conditions in infrastructure, industry, and construction.

lifecycle and recyclability

Geoprime products can be reused and recycled throughout their life cycle. Geoprime waste can be used to make concrete aggregate.

The technical feasibility of concrete aggregate made of waste material should always be examined seperately.

Please send us a message, and we'll get back to you shortly.

Sign up to receive updates on sustainable solutions and low-carbon materials from Betolar.