Betolar Plc

Press Release

12 June 2025 at 2.30 A.M. EEST

Betolar Plc: Building the Future from Waste – High-Performing Green Cement Revolutionizes the Industry

Betolar's advanced metal separation technology enables the purification of industrial slag, and mine tailings achieving a 99 % metal yield and allowing for the recovery of valuable critical and strategic metals. After purification, the remaining slag is no longer waste – but a valuable raw material for the production of green concrete.

Based on recent test data, the 28-day compressive strength of this green cement fully matches the performance of traditional Portland cement and clearly exceeds the strength of binder made from blast furnace slag. Its high reactivity and excellent activity index make it a competitive alternative for various construction and mining applications.

Green cement is also a cost-effective circular solution that enables the reduction of the carbon footprint on an industrial scale by up to 90 % compared to traditional cement production – without compromising quality or performance.

With Betolar’s metal separation technology, both recovered critical and strategic valuable metals and low-carbon green cement can be produced from the same raw material stream, such as non-utilized metallurgical slag or mine tailings. This combination creates significant added value for both the environment and business – a truly sustainable solution where waste becomes valuable raw material.

Green Cement Offers Significant Environmental Benefits and Opens New Opportunities in Sustainable Construction

The production of green cement is based on the utilization of industrial sidestreams, which reduces the use of virgin raw materials and significantly lowers the carbon dioxide emissions of the manufacturing process. At the same time, it helps reduce the environmental load of waste areas – such as land use, dusting, and leakage into nature.

The market potential is significant. For example, the annual amount of unutilized slag from the steel industry alone, approximately 500 million tons in the world, would cover about 10 percent of the world’s cement needs when processed using Betolar’s method. The construction industry is now actively seeking low-carbon solutions, and the demand for low-emission raw materials such as green cement is expected to grow strongly in the coming years. Depending on the source, the estimated average annual growth rate is 20-30% towards the year 2030, which would mean a multiplication of various applications of Betolar's material technology by the end of the decade.

"Betolar's green cement not only matches the performance of traditional Portland cement but also offers significant environmental and cost benefits. This is an important step towards more sustainable construction and value creation based on the circular economy," says the company's President and CEO Tuija Kalpala. "Our metal extraction technology enables both the efficient recovery of valuable metals and the production of low-carbon green cement from the same material stream. This is a significant breakthrough in the comprehensive utilization of industrial sidestreams and mine tailings," Kalpala continues.

Betolar Plc

For more information:

Tuija Kalpala, President and CEO, Betolar Plc, tel. +358 50 567 6608, tuija.kalpala@betolar.com

Jyri Talja, Chief Growth Officer, Betolar Plc, tel. +358 40 192 3143, jyri.talja@betolar.com

About Betolar

Betolar is a circular economy enabler and materials technology specialist, providing innovative solutions to help use industrial sidestreams to produce low-carbon and cement-free products for the mining and construction sectors. Betolar's mission is to help reduce carbon emissions and the use of virgin resources in mining and construction.

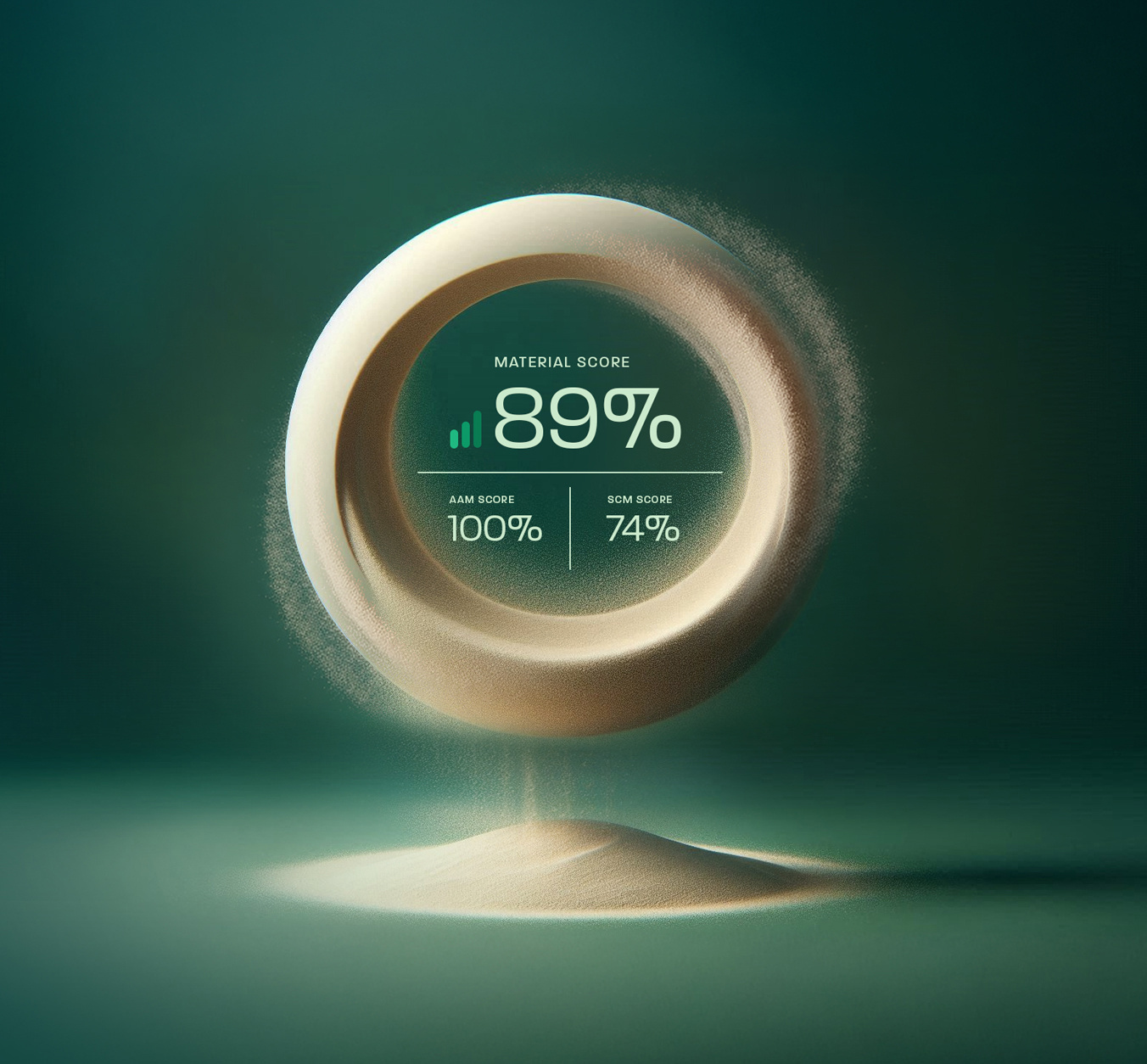

Betolar's circular economic innovations significantly reduce CO2 emissions from cement use and the use of virgin raw materials by utilizing industrial sidestreams. Betolar is continuously developing its low-carbon Geoprime solution for the mining, metals and construction industries. In addition, Betolar's AI-based data platform creates value from industrial side streams and accelerates solution development. The SidePrime analytics service, based on the data platform, maps the potential for utilization of industrial sidestreams and waste.

Betolar was founded in 2016 and is domiciled in Kannonkoski, Finland. Betolar is listed on the Nasdaq First North Growth Market. For more information www.betolar.com.

.jpg)